If L&D is going to be successful in delivering quantifiable business value, employee learning must have a clear link to business results.

When you focus on your business objectives first and then create a corporate training program to deliver on those objectives, you will reach the organisational objectives with more ease.

Companies such as Walmart and Bloomingdales have already discovered this to be the case.

It sounds simple doesn’t it? However the unfortunate reality is that many organisations seem to have the process back to front. They have well thought out training programmes but they are designed without the business objectives in mind.

Therefore the objectives that employees, departments, and divisions are working towards are not instilled through the corporate training program.

Employees are a fundamental part of the organisation and if it is going to achieve its business goals, employees’ knowledge should be aligned with those same goals.

In the simplest of terms, what an employee knows will directly impact on how they act, and you need them to act in a way to deliver on the organisational strategy.

This is our 4 step method to put the business first in a real organisational environment:

STEP 1 – Start by thinking of the end: Consider what the organisation is trying to achieve and work backwards to departmental and individual objectives.

It is of primary importance that you have a clear understanding of the specific business outcomes you are trying to achieve. Without this knowledge, how can you possibly create a corporate training program to reach these goals? The first step is to work with the business to understand their objectives.

An example of a corporate objective might be to reduce work related injuries by 5%. It may be determined that forklift accidents will need to be reduced by half, which means each forklift operator will have an objective to have no more than one safety incident per year.

STEP 2 – Set the behaviours/job actions expected of employees for objectives to be achieved

The next part of the process is to consider the ideal behaviours that employees will need to perform to achieve the outcomes consistently. Continuing our prior example, a common source of forklift accidents is tipovers which are caused by items being incorrectly loaded.

We could break this down into specific behaviours needed to prevent tipovers:

- Ensure each load is within load limit recommendations

- Take note of the recommended load center and position accordingly

- Do not add extra weight in an attempt to counterbalance an overload

- Ensure loads are close to the front wheels to maintain stability

STEP 3 – Identify the learning employees require to enable them to exhibit the right behaviors

By this step we know the behaviors we want employees to exhibit and we need to decide how we can build that knowledge so they do perform correctly.

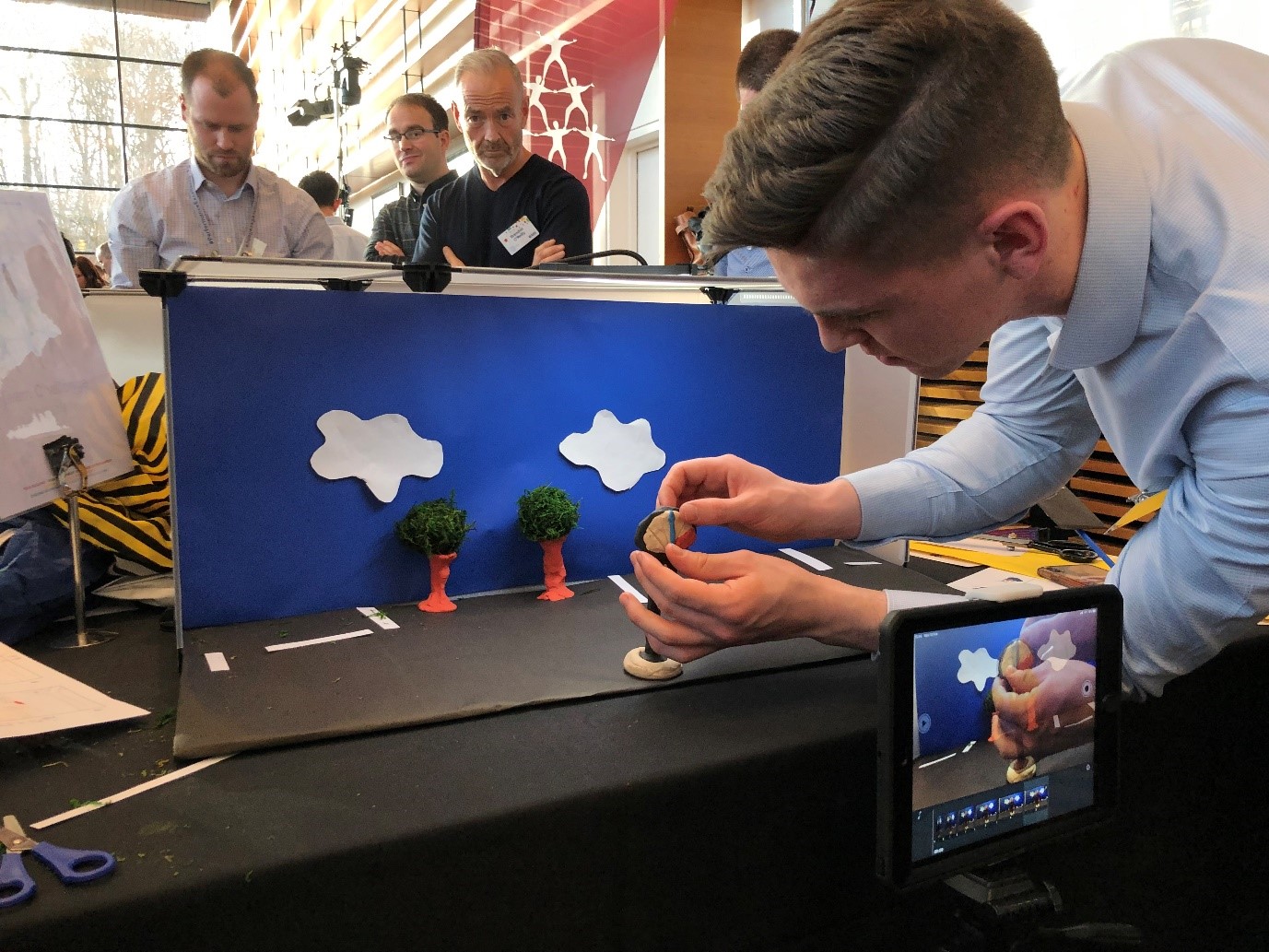

Our recommendation would be microlearning, which is learning delivered in bite sized chunks, preferably daily to build knowledge and keep it front of mind.

Back to our forklift example, microlearning content might be as follows:

- Acceptable load weights

- Acceptable container sizes

- Lifting a load correctly

STEP 4 – Frequently monitor employee job actions/behaviours, measure results and adjust the learning program

Since you have defined low level behaviours and the learning content that helps employees understand how to deliver on these behaviours, you now have a consistent framework for observation and measurement.

As an example, a manager might monitor the following operation job actions/behaviors:

- Number of loads within recommendations

- Number of times the operator positions the load correctly

- Number of times an operator adds extra weight to counter balance

- The average distance loads are positioned from the front wheels

It becomes easy to identify where employees are having success or difficulties through measuring knowledge growth against the application of defined behaviours. By measuring behaviours according to defined objectives, it allows you to determine if the behaviours are having a positive impact.

If you recognise any issues, you can adjust the defined behaviours and the learning content being delivered to achieve the business objectives you are trying to achieve. In an example where the operator is still experiencing tipovers, by documenting specific job actions/behaviours it will allow you to identify how the operation can be improved, and perhaps a specific area of learning the operator needs more of.

It is an iterative process whereby you evaluate performance and job behaviours and then identify any weaknesses and deliver tailored learning to eliminate defects.

L&D tracks the learning success on each of the learning topics, and analyses that data to understand where improvements have been made in observed employee behaviours. It becomes easy to link performance improvements to the achievement of departmental objectives which is an important tool for managers.

Give this approach a try and we are confident you will be impressed with the results.